PRODUCT DESCRIPTION

With large-diameter piping and low differential pressure devices, the DHI portable flare stack is designed to minimize back pressure on storage tanks and other low-pressure vessels.

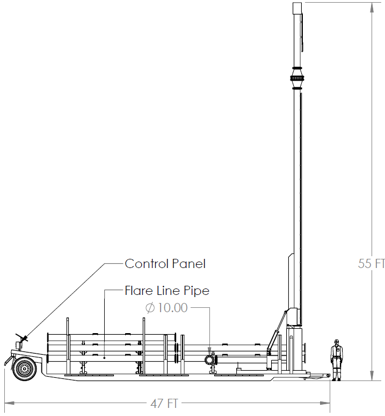

The flare stands at 55 feet in the standard form and may have extensions added to a maximum of 66 feet.

This includes over 222 feet of flare on adjustable stands, permitting control of the gradient of the line while preventing fluid collection in the flare line.

DHI’s new flare system features a wide boar flowline and a 10-inch flare stack designed to permit low-pressure storage tanks to vent gas to combustion, thereby safely minimizing back pressure on the tank battery.

Example: Tank back pressures at 8 oz/sq.in, flowing approximately 4.4 MMscf/day.

APPLICATIONS

Flaring gas and vapors from production operations

High volumes of gas flaring rates

Extremely low back pressure scenarios

BENEFITS

Permits venting and combustion of vapors and gases from low-pressure storage tanks

Able handle large flow rates and intermittent high and low flow rates

Occupies less space with no need for long, extended stabilizers

Vertical flame arrester prevents liquid build-up

Quad zero compliant

FEATURES

Easily portable

Includes large diameter flare lines

Hydraulic elevation

Continuous pilot

Ignition monitoring

Auto ignition & remote control

Natural gas or propane pilot gas

Wind-resistant up to 100 mph

Solar-powered ignition and control

HEAT RADIATION

The heat radiation given off by burning flare stacks must be managed to keep the working area on location safe in accordance with industry standards. The adjacent chart shows ground level heat radiation at various flare flow rates.

Specification Sheet Request